Powder Testing and Certification

Navigating the world of Aluminum Fencing and powder coating can be complicated at first glance since there are many options for manufacturers to call their product Made in the USA.

At Antebellum, we make it easy for you to understand our process. We take great pride in our commitment to American manufacturing. Our fence is fabricated, assembled and powder coated right here in Ocala, FL and we exclusively employ TCI Powder, a trusted domestic manufacturer, for our powder coating process.

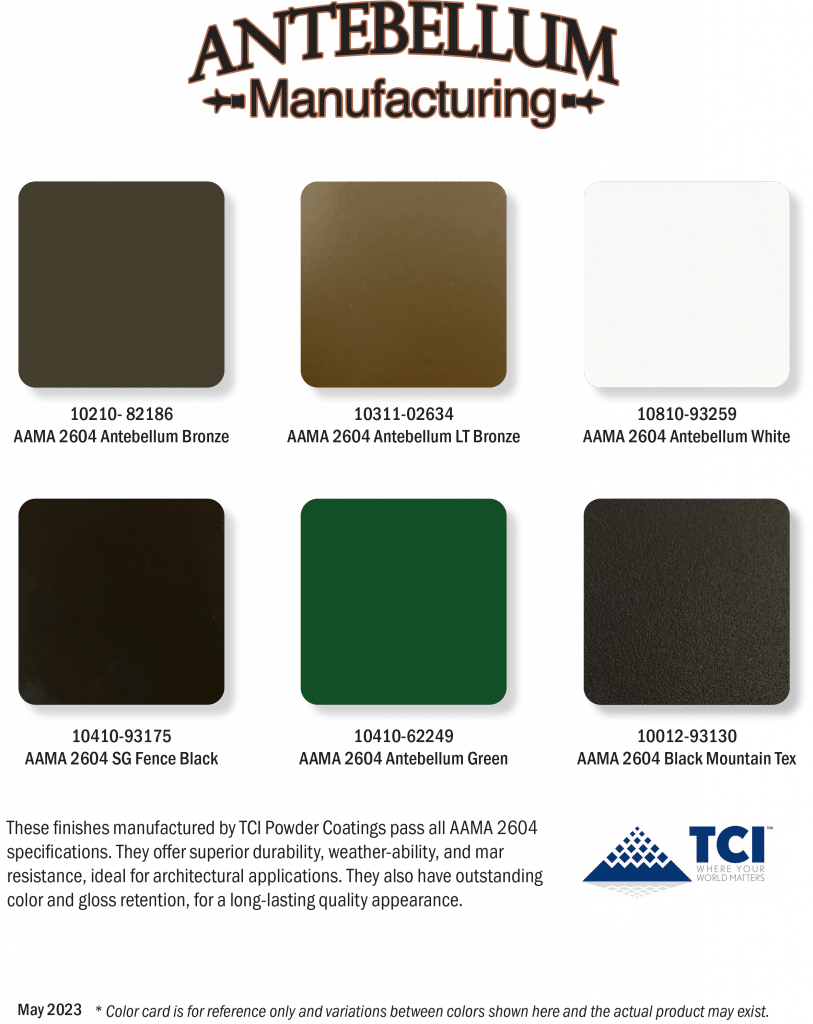

As part of our applicator certification, our products are tested by TCI Powder for compliance. Antebellum Manufacturing uses AAMA 2604 compliant Powder coat unless a customer specifically requests otherwise.

Current and previous testing includes Salt Spray and UV (ASTM B117, QUV WEATHERING, AAMA 2604 & AAMA G-85).

About Our Process

In 2018, we demonstrated our commitment to powder coating with the installation of a brand-new state-of-the-art Gema powder booth and automated gun system. Our new system incorporated a washer/pretreatment system and cure oven that would ensure our ability to be AAMA 2604-2605 compliant moving forward. These elements combined form the conveyorized finishing system in place today.

Early 2019 we established a partnership with TCI Powder Coatings as our exclusive powder supplier. TCI is a domestic manufacturer specializing in the manufacturing of powder coatings. Improvements to our finishing process, because of the powder formulation devised by TCI, were both immediate and significant.

In 2019, Antebellum Manufacturing successfully attained TCI Certified Applicator status. Following an extensive powder coating line and process audit, our coated parts underwent Salt Spray tests to verify compliance with AAMA certification. This was accomplished in all instances. This certification further highlights our commitment to quality and demonstrates our capability to meet the necessary standards.

Further testing of Antebellum products:

- Passed ASTM G85 – Standard Practice for Modified Salt Spray (Fog) Testing – The G85 cyclic corrosion testing (CCT) is intended to be a more realistic way to perform salt spray testing than the traditional ASTM B117, steady state exposure. The actual atmospheric exposures usually include both wet and dry conditions, making these accelerated laboratory tests correlate better to natural cyclic conditions. Case 21788 (SS-2869) achieve 10,000 hours with all rating being 10. These coatings and pretreatment are first in class.

The AAMA 2605 requirement is a scribe rating of 7 or higher and a blister rating of 8 or higher after 2,000 hours of exposure. The Antebellum products tested by TCI exceed this consistently. This is not easily achieved; it takes both excellent pretreatment and a durable coating.